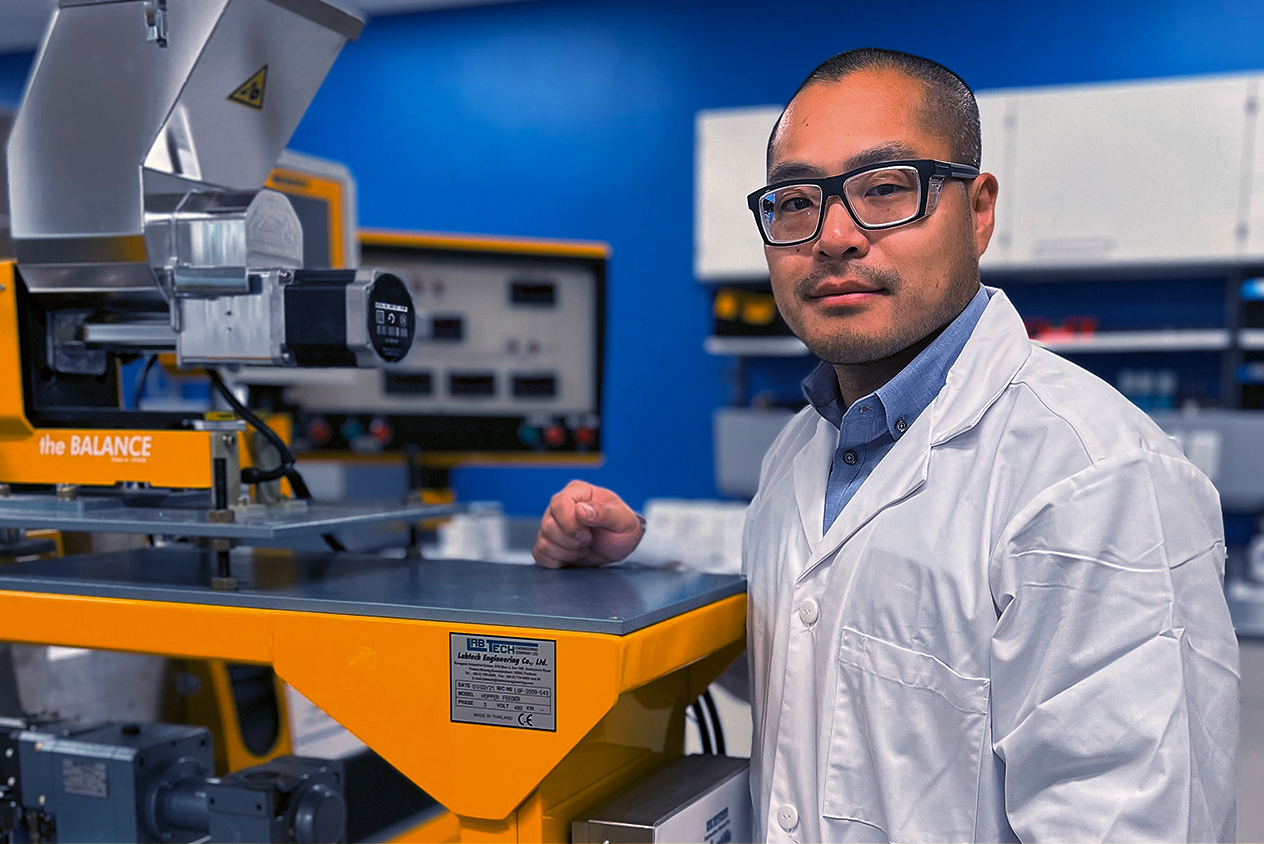

Plastics manufacturers need TiO2 pigments that can readily and efficiently incorporate into their polymer matrices and that provide bright white surfaces with optimum opacity and tinting strength. Depending on the end application of the plastic, the requirements placed on the TiO2 pigment can be very demanding. For example, the pigment must hold up to produce highly loaded pigment masterbatches for high temperature melt extrusion coatings and lacing free blown films, or to achieve excellent thermal stability in products made of polycarbonate or for white, durable window frames made of PVC. Our plastics laboratory is equipped with an array of machines typical for processing different types of plastics and the incorporation of TiO2 pigments into these systems.

Our Technical Services Team has comprehensive knowledge on topics related to TiO2 in polymer matrices. In the plastics laboratories, KRONOS’ Technical Services Team can determine the performance of TiO2 in plastic applications, such as PVC, polyolefins, styrenes and engineering plastics, including their optical properties, melt flow index for viscosity, their state of dispersion, pressure filtration performance and, where required, their resistance to lacing in blown films and mixing characteristics.